Material Throughput Monitoring

Product Highlights

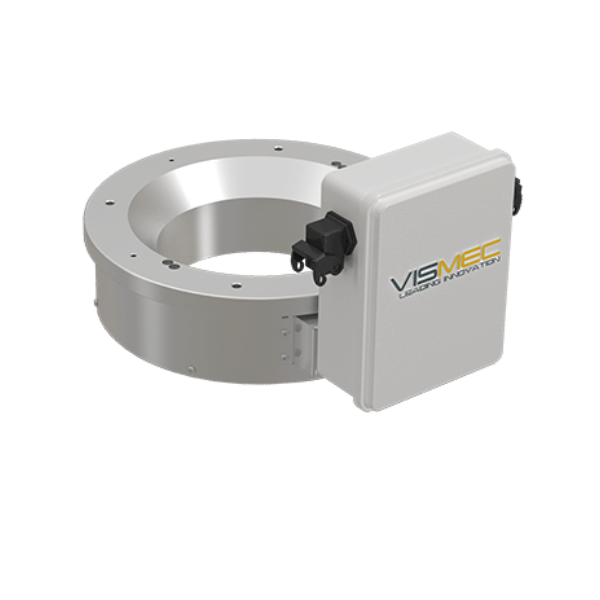

The Halo from Vismec, is a very useful, highly accurate device to gravimetrically monitor material throughput. Enabling optimal drying of plastics by continuously monitoring drying parameters. Its ability to optimise drying conditions in real time save considerable amounts of energy, material degradation and time.

It allows you to get accurate control of your plastic productions main cost: your raw material.

The dryer and drying parameters are controlled by the Halo, adapting automatically to the production process in real time. You can set an alarm for exceeding the maximum throughput avoiding conveying of eventual undried material to the production machine.