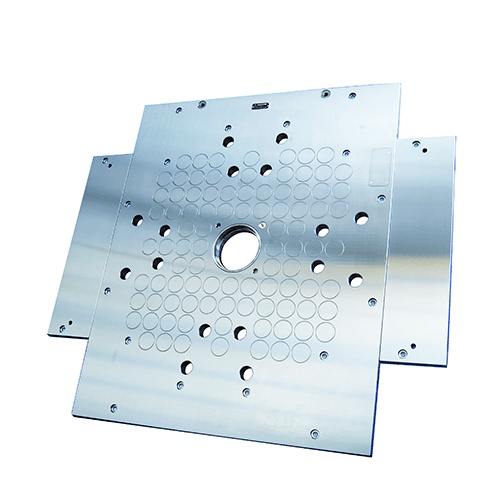

Magnetic Platens

Product Highlights

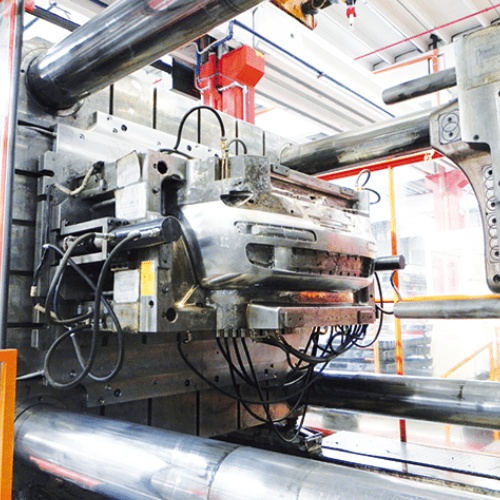

Companies who have frequent mould changes, especially with heavy tools, can remove and install a new tool in minutes. Our magnetic platens dramatically increase production results.

PressTec GRIP is the most advanced magnetic fixing system: Stems from 20 years of specific experience and over 10,000 equipped presses. It is extremely reliable: There are no components subject to wear, deformation or thermal expansion.

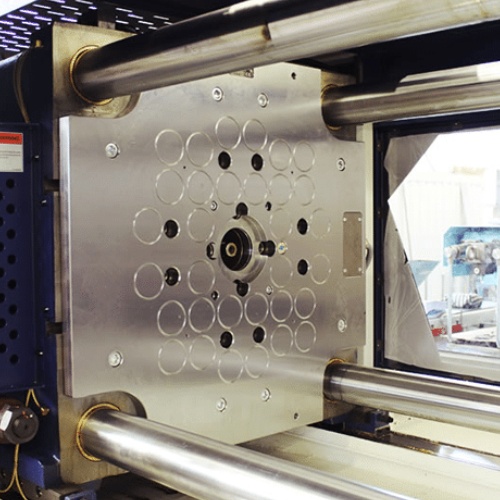

What are Magnetic Platens?

Magnetic platens allow a rapid, safe and practical tool change in the injection moulding process. This system is designed to meet the demands of a lean manufacturing process. Machines equipped with magnetic platens are significantly more productive.