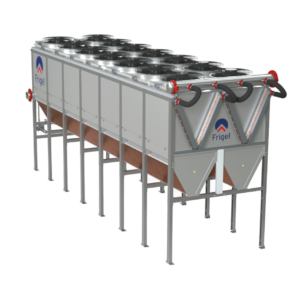

Summit Systems is the exclusive supplier of Frigel products in the UK

Quick delivery times with a large stock of Frigel machinery

Comprehensive service support, including installation and training

Frigel brings over 70 years of experience in cycle time solutions

Continuous product development for enhanced efficiency

Cost savings and quality control by investing in Frigel machinery

Why Choose Microgel Syncro?

Microgel Syncro represents an innovative technological advancement from Frigel, transforming the temperature control process for injection moulding of technical components.

This cutting-edge Microgel Syncro technology delivers remarkable benefits in the injection moulding process, including a substantial reduction in cycle time by up to 40%, ensuring the production of high-quality products. In perfect digital harmony with the mould, Microgel Syncro exclusively supplies cold water during the cooling phase, leading to a significant reduction in cooling time while maintaining optimal mould cavity temperatures during the injection phase.

This technology revolutionises the way temperature control is managed in injection moulding, allowing for faster and more efficient production while maintaining the quality of the final products.

Why Choose Summit Systems?

Selecting Summit Systems as your process cooling partner offers a strategic advantage due to our partnership with Frigel, a company with over 50 years of expertise in process cooling. Beyond providing cutting-edge cooling solutions, Summit Systems excels in offering comprehensive turnkey projects for automating complete mould or extrusion shops. With a deep understanding of industry requirements, we provide tailored solutions to enhance efficiency, reduce downtime, and improve precision. Our commitment to reliability, customisation, and exceptional support ensures consistent performance, making Summit Systems a trusted choice for optimising your process cooling needs.

What Are The Benefits?

What makes the Microgel Syncro different?

Digital Synchronisation

The technology is digitally synchronised with the mould cycle, ensuring that the cooling process aligns perfectly with the production requirements. This contributes to optimal part quality and cycle time.

Parameter Storage

Microgel Syncro offers the ability to memorise and store parameters for each mould, known as "recipes." This feature simplifies setup and ensures consistency in production quality across different moulds.

Energy Analysis

The system provides real-time analysis of energy consumption, measured in kWh/kg. This data allows you to monitor energy efficiency and make informed decisions for further optimisation.

Remote Connectivity

Microgel Syncro typically offers integrated remote connectivity, enabling you to monitor and control the system remotely. This feature enhances convenience and ensures you can manage your processes from anywhere.

Online Recipe Finding

The technology often includes an online wizard for recipe finding specific to your moulds. This simplifies the setup process, especially for new moulds, by guiding operators through the configuration steps.

DRASTICALLY REDUCE CYCLE TIMES

Get In Touch Today to Discuss

Your Cooling Requirements

Together, we can revolutionise your cooling processes, enhance your productivity, reduce your cycle time and improve product quality.

+44 (0)1827 213 401

hello@summitprocesscooling.co.uk