Plastic Packaging Tax 2023 Update

29 March 2023

To tackle the issues of Plastic Pollution, the Plastic Packaging Tax came into effect in April 2022. Plastic packaging containing less than 30% recycled plastic will be subject to the Plastic Packaging tax (PPT). Companies faced being charged £200 per tonne on any plastic packaging containing 30% or less recycled material.

2023 Update

Effective 1 April 2023, the rate of PPT will increase to £210.82 per tonne (from £200 per tonne).

The HMRC Guidance issued on 15 March 2023, reminding businesses that they must register for the UK Plastic Packaging Tax if they:

- Expect to import into the UK or manufacture in the UK 10 tonnes or more of finished plastic packaging components within the next 30 days

- Have imported into the UK or manufactured in the UK 10 tonnes or more of finished plastic packaging components since 1 April 2022

Effective 31 March 2023, the retrospective test will apply on the last day of every month i.e., businesses must register for the Plastic Packaging Tax if they have imported into the UK or manufactured in the UK 10 tonnes or more of finished plastic packaging components in the previous 12 months.

Learn more: https://www.ey.com/en_gl/tax-alerts/uk-increases-plastic-packaging-tax-rate

Summit Systems are here to help you.

If you are producing packaging which predominantly (by weight) comprises of plastics components, and does not contain 30% or more recycled material, you will be liable to the tax.

Examples:

- If you produce a bottle top ready to be placed on a bottle, you will be liable to pay the tax.

- If you produce food packaging which is predominantly made of plastic, you are liable.

How can Summit Systems help me incorporate 30% recycled material?

Summit Systems are working with UK Plastic Recyclers to help businesses avoid the tax and utilise higher levels of recycled material in their production process. We have a range of granulators and dosing units from 4 global suppliers designed to improve the percentage of recycled material within your plastic production processes: Maguire, Movacolor, Tria and Zerma.

As is our role within the plastics industry, our aim is to provide the most efficient and cost-effective ancillary equipment on the market, and with the products in our portfolio we can provide a multitude of options to enable your business to exceed the 30% recycled content threshold.

Blending & Dosing Units

With the use of a blending or dosing unit, regrind can be reintroduced back into the manufacturing process. Summit Systems supplies Blenders and Dosers from leading suppliers Maguire and Movacolor, both of which boast phenomenally short payback periods.

These blenders and dosers are designed to accurately mix multiple materials including regrind and recycled polymer. At the same time, the exact weights of each component are monitored extensively, using touchscreen and smart software technology, which can then be recorded for full traceability, which is critical for completing your Plastic Packaging Tax Return.

The Maguire WSB Gravimetric Blenders are configured with the appropriate size hopper and dispense device for the required material. The new dispense devices were designed to help manufacturers with new sustainability challenges, making it easier to handle difficult materials, and increasing the usage of regrind in their processes. Covering applications for up to 12 materials, customers benefit from precision mixing, simple operation, and minimum set up time.

The Movacolor Gravimetric Doser series uses loss-in-weight weighing system and dosing cylinder technology. Feeders are equipped with a touchscreen controller with MCSmart software, which gives you full control over your extrusion, injection molding or blow molding process. To broaden the successful gravimetric feeder product line, Movacolor placed their focus on the difficulties plastic producers faced when dosing hard to handle materials like regrind, powder or liquids; the MCTwin was developed to dose additive masterbatch and regrind simultaneously. The uniqueness of this system is that any waste material produced from the product is immediately returned into the process. As the material is already coloured, the responsive system automatically adds fewer colour granules, avoiding the over consumption of additives and reusing the maximum of regrind which results in significant costs savings.

Granulators & Shredders

If you are producing regrind in-house rather than purchasing from a third-party, our range of granulators guarantees the right product for the right application: low speed granulators for beside the press operation, edge trim and thermoform specialist, miniature machines for low volume recycling or engineering plastics and large heavy-duty granulators for general recycling.

The Tria Multi-Purpose Granulators are ideal for recycling both rigid and flexible materials such as sprues, injection molded, or extruded parts. The range has the lowest running cost per kilo of any machine on the market and offers extremely robust and reliable machinery, creating quality regrind for re-use into production processes.

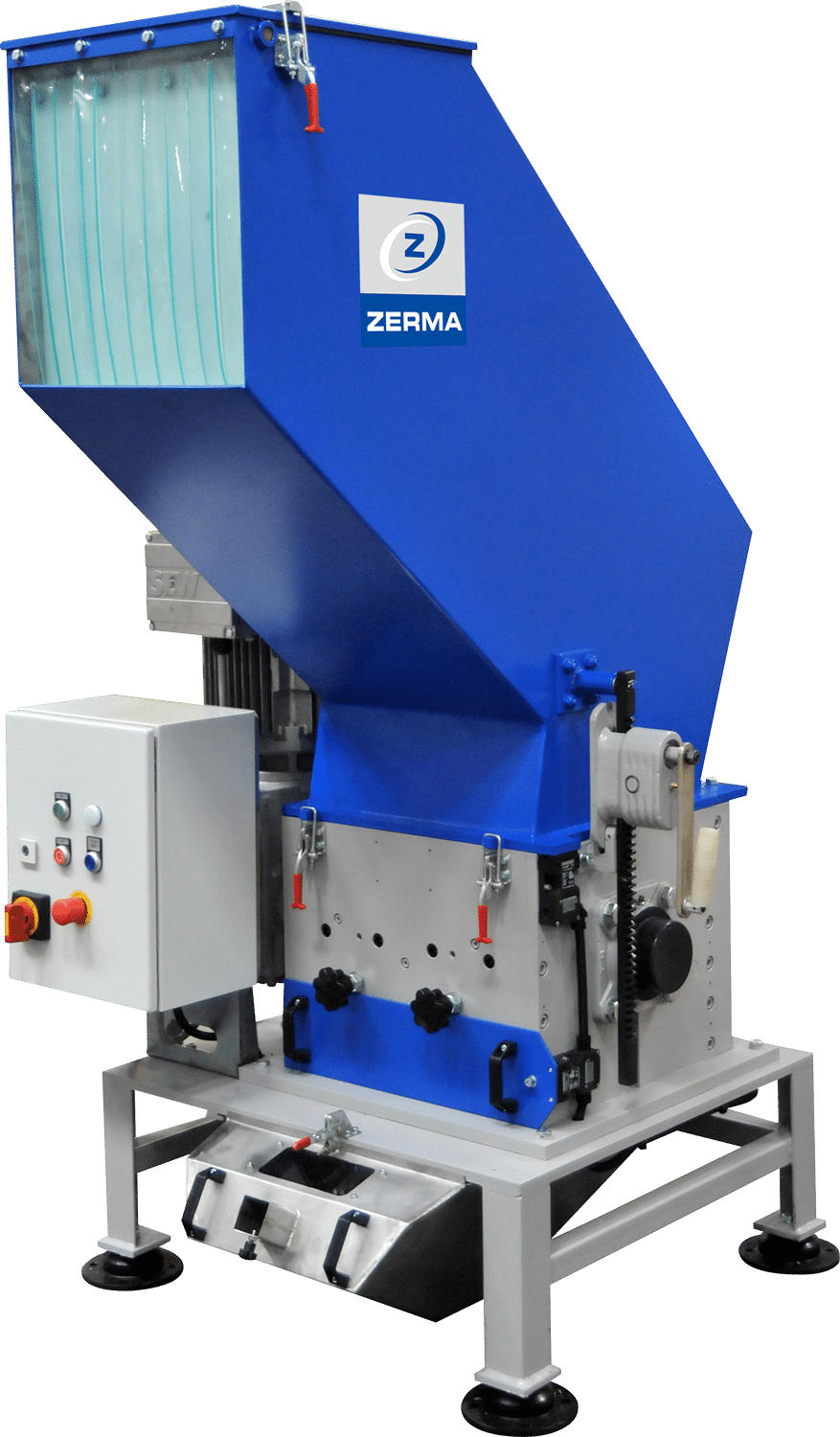

An alternative option is the Zerma Heavy Duty Granulator GSH, this model is ideal for tough applications which include 24/7 recycling. A dependable machine with a typical throughput of 300-700kg/hr. with heavy-duty bearings and V-cut knife design gives efficient cutting with low dust.

Why should I choose Summit Systems?

For over 30 years Summit Systems has been supplying and installing plastic ancillaries and recycling machinery. We are passionate about ensuring that our customers have the most cost-efficient and advanced technology which ensures their plastics processes run smoothly and without fault. And with the introduction of the Plastic Packaging Tax, we are even more driven to help our customers adapt to the changes of meeting or exceeding the 30% recycled material threshold.

If you would like further information on how Summit Systems can help you improve your granulating and dosing processes, email us at info@summitsystems.co.uk.