Microgel Syncro Technology improves Quality and Production

17 October 2023

Microgel Syncro Technology: GelliPlast has embraced Frigel's cutting-edge Microgel™ Syncro technology to enhance both product quality and production outcomes. This strategic choice reinforces GelliPlast's position in the market, underscoring their commitment to customer satisfaction. GelliPlast's significant investments in pioneering technology, analytical research, and development further solidify their dedication to excellence. The integration of Microgel Syncro technology has marked a transformative milestone in GelliPlast's mould cooling processes.

Frigel, founded in 1960, is a worldwide manufacturer of cooling and temperature control systems, but also the ideal partner and technical consultant with the ability to identify the best solutions, in terms of performance, efficiency and environmental impact.

Established in 1978, GelliPlast originally specialised in moulding plastic materials for the footwear industry. Over the years, the company's continuous expansion has positioned it as a prominent leader in manufacturing components for a diverse range of sectors, including railways, food, and lighting.

Since 1990, GelliPlast has maintained an in-house laboratory equipped with state-of-the-art technology and staffed by specialists dedicated to conducting qualitative analyses of the raw materials used in production. Additionally, they rigorously assess the different production batches generated daily, ensuring a steadfast commitment to delivering exceptionally high-quality standards.

The relationship between GelliPlast and Frigel was born in the early 2000s when Fabio Gelli got in touch with Frigel with the intention of deepening his knowledge of injection moulding cooling. Frigel offered high-performance machinery and highly professional assistance. For over twenty years now GelliPlast has relied on Frigel and its custom-designed solutions to optimise production processes in the plastic and rubber sector.

The Corporate Approach

GelliPlast operates in both national and international markets and produces components with different types of plastic materials in various shapes and sizes. Over the years, GelliPlast has grown thanks to the ability to manage large production volumes while still maintaining product quality. To support this type of production, continuous investments in research and development of materials, qualitative analysis of the finished product and the adoption of new technologies was necessary.

The production area has 26 lines, with 25 injection presses from 80 tons to 1500 tons, and a total of 559 active moulds and 369 different types of raw materials are used, for the creation of 2147 finished products.

The resin production department is equipped with an innovative dehumidification system used for polyamide articles in order to improve their mechanical and aesthetic characteristics. The department is completed by a highly automated line with anthropomorphic robots and a laser cutting centre dedicated to specific processes with high quality standards.

The Challenges

GelliPlast has consistently faced a series of ongoing challenges throughout its journey, including:

- Technological Advancement: The imperative to remain at the forefront of technological innovation is paramount. GelliPlast is committed to staying ahead of market trends, proactively anticipating demands, and implementing cutting-edge machinery.

- Proactive Consultation: GelliPlast actively collaborates with industry professionals capable of providing valuable expertise and practical solutions to address the numerous complexities inherent in a high-value component molding facility.

In recent years, substantial investments have empowered GelliPlast to venture into the development and branding of its own product lines. One of its most recent innovations, the Flexy Dream, is a modular support system designed for bed slats and has already received international patent recognition.

GelliPlast continued to place its trust in Frigel: with at least one Frigel unit on each of the 25 injection presses. Microgel Temperature Control Units intelligently manage hundreds of different moulds which are alternated week after week.

“Each press has its own recipes set directly on the Microgel, recipes that can be reused over time, which makes everything easier and well planned. The line manager keeps production under control and has the possibility of acting directly on the temperature control parameters to optimise the quality of the product and reduce waste” - Filippo Gelli, Production Manager

GelliPlast made it possible to install Syncro on a particular line with a technical finish. Given the performance obtained, GelliPlast has chosen the new Microgel Syncro technology as standard for all new installations.

Syncro Technology

Microgel RSY Syncro is revolutionising temperature control in the injection moulding of technical parts. The new approach is based on the complete integration between the mould temperature control system and the injection moulding process. It allows for a significant reduction of the cycle time, of up to 40%, guaranteeing a very high quality of the finished product.

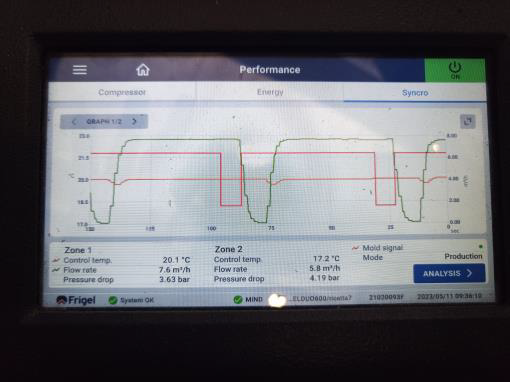

Digitally synchronised with the mould, Microgel Syncro delivers cold water only during the cooling phase, drastically reducing the cooling time and keeping the mould cavities warm during the injection phase.

- Increased productivity by up to 60% due to the significant reduction in cooling time.

- Improves product quality in terms of dimensional tolerances, structural characteristics, and aesthetic finish as a result of better mould filling.

- Efficiently manages energy consumption through reduced injection pressures, decreased hot runner usage, and lowered clamping forces.

The Results

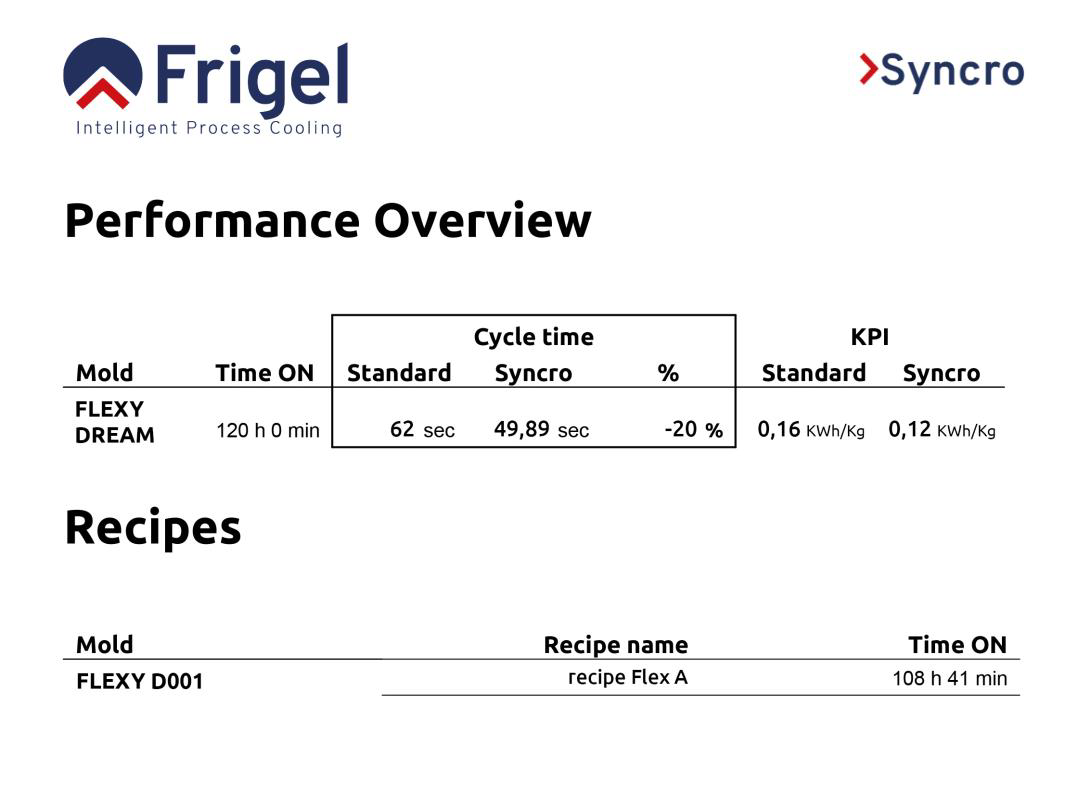

With the valuable support of Frigel, GelliPlast utilised an online tool to fine-tune their machinery, ultimately discovering the perfect recipe for their Flexy Dream application. Every week, a detailed performance report is sent out, providing insights into the machine's production and operation. The adoption of Microgel RSY Syncro has yielded remarkable results for GelliPlast, significantly enhancing their competitiveness in the market as they introduce the innovative Flexy Dream product.

“The cycle time from 62 sec has passed to 50 sec, with a decrease of about 20%, against a consequent increase in productivity” - Filippo Gelli, Production Manager

Over the years, GelliPlast has gone from installing the first versions of Microgel RC up to the current RS Series and the revolutionary model RSY Microgel Syncro.

“The adoption of Microgel Syncro has offered us the possibility of winning an order that we would otherwise have lost. The reduction in cycle time, waste and dead times has allowed us to significantly lower production costs”- Filippo Gelli, Production Manager.

The project also included the installation of the Netgel MiND™, a supervision system that monitors every single Frigel machine in the plant in real time. MiND is the ideal diagnostic solution that can facilitate the business transformation process towards INDUSTRY 4.0. It makes data reading and analysis immediate at any time, on any device.

“MiND allows us to keep production under control at any time of the day, even when we are away for work or on vacation. If the new generation plant weren't monitored by MiND, we wouldn't feel as relaxed as we are now. From outside the office, I can receive machine/system block alerts on my smartphone. I can immediately contact the shift manager to check the systems. In a few tens of minutes, by analysing the type and location of the error, it is possible to identify the problem quite easily, for example: the water filter is blocked. Thanks to MiND and the reactivity of Frigel service, a small complication is resolved quickly. Years ago, similar episodes would have stopped production for hours” - Filippo Gelli, Production Manager.

In conclusion, the partnership between GelliPlast and Frigel has exemplified the power of innovation, collaboration, and forward-thinking solutions in the realm of injection moulding. GelliPlast's commitment to staying ahead of market demands and their dedication to continuous improvement, combined with Frigel's expertise in temperature control systems, has resulted in a remarkable transformation of their production processes.

The adoption of Microgel Syncro technology, with its intelligent temperature control and synchronised operation, has not only significantly reduced cycle times and enhanced product quality but has also elevated GelliPlast's competitive edge in the industry. The success story of GelliPlast and Frigel serves as a testament to the positive impact of embracing cutting-edge solutions and Industry 4.0 practices, ultimately paving the way for more efficient, productive, and sustainable manufacturing processes.

If you're inspired by the outstanding results achieved by GelliPlast through their collaboration with Frigel and want to accomplish the same benefits for your operations in the UK plastics industry, Summit Process Cooling is your dedicated partner who will deliver Frigel's cutting-edge technology and expertise right to your doorstep. Whether you're seeking to optimise production, improve product quality, or enhance your overall efficiency, reaching out to Summit Process Cooling will open the door to a world of innovative solutions and industry-leading support. Don't miss the opportunity to elevate your manufacturing processes to new temperatures – contact Summit Process Cooling today.